M14 /M1A NM SPRING GUIDE Solid 1-Pc Design - Precision Machined - Fully Hardened

The Sadlak Industries National Match (NM) Spring Guide brings the evolution of this critical National Match (NM) quality part one step beyond the Brookfield Precision Tool spring guide. Although our spring guide is based on the Brookfield design with the machined mag catch, shaft, and flats, we didn't want to take the chance that the weld operation had any adverse effect on the finished product. So, we took the extra time and expense of machining the entire spring guide from a solid round stock. This assured perfect alignment of the mag catch with the shaft, and allowed for uniform heat treating of the whole part.

National Match Spring Guide - Part No. 140020

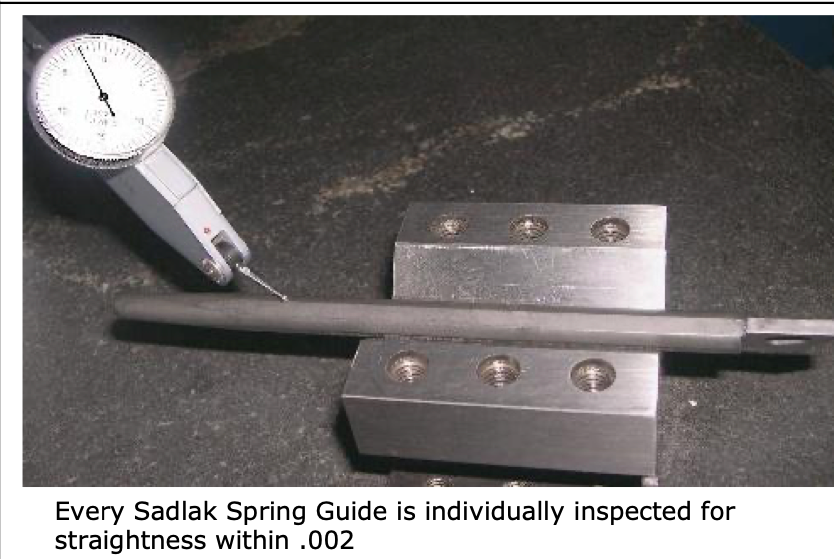

The Sadlak spring guides are hardened to the original USGI spec. 40 - 44Rc. In addition, each of our NM spring guides is hand inspected for straightness within .002 max. over the length of the guide. The result of this attention to detail is a spring guide which weighs 64 grams (2.3 oz), has the straightness to properly align the spring without binding, and the hardness to stand up to extended use without appreciable wear.

Our NM spring guides are produced to the same specifications as the military’s national match rifles. The precision is enhanced by making them from one solid piece of round 4140 chrome-moly tool steel, with no welding to cause distortion. Each is case hardened to 40-45 HRc in an inert gas furnace to help maintain straightness and uniform hardness for long service. They are finished with a corrosive-resistant mil. spec. manganese phosphate (aka parkerized). What makes our NM spring guides unique and more accurate is our precision alignment of the magazine catch to the guide shaft. This is achieved by turning the .344 diameter shaft from a larger diameter solid rod. The magazine catch is then precision CNC machined while being located from the guide shaft. Four flats are milled into a .344 shaft body to reduce the weight and friction between the spring that adds to the smooth action, while precisely guiding the operating rod.

|

Why a Sadlak NM Spring Guide?The Sadlak National Match Spring Guide improves the consistency and smooth motion of the operating rod. This helps reduce wear and increases rifle accuracy over the standard stamped GI guide. This NM Spring Guides is NOT made from a cut-off stamped GI guide welded to a round drill rod. These make-shift NM GI guides often have a soft magazine catch caused by the welding, and may not be precisely aligned because of poor fixturing.Field Tested:This product has been field tested in national matches by Dave Ferrante of Heart Mountain Precision Machining, who is a gunsmith and distinguished high-power M14 rifle competitor. Approximately 4000 rounds have been fired from his match rifle using our spring guide, with no appreciable wear on the catch or shaft. Mr. Ferrante states, “It’s the finest quality guide out there.”Features:

|

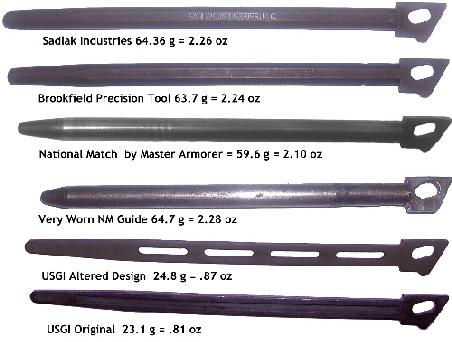

Brief Evolution of the M14 Spring Guide:

6 – 5 – 4- 3 –2 – 1 –

Sadlak one-piece design

BPT welded with precision catch TRW NMversion Hybrid: very worn NM round drill rod with soft, welded magazine catch cut-off from USGI stamped guide USGI alternate design flat-stamped rectangle USGI original flat-stamped rectangle design |

|

|

|

|

Sadlak Industries was proud to have been selected to equip a National Guard unit with steel scope mounts, spring guides and Titanium Nitride coated pistons to upgrade their rifles prior to their deployment to Iraq. We spent a day with the troops helping them to assemble their mounts and zero-in the steel scope mounts on their M14 rifles.On September 22nd, 2004, Mike Sadlak (bottom center left) and Brad Palmer, retired U.S. Army and coach of the Connecticut Junior High Power Shooting Team (center right) were the guests of the detachment pictured below. These ten 2-man surveillance teams consist of airborne, ranger, and sniper qualified soldiers who received the accurized M14 with the Sadlak steel scope mount, spring guide and TiN-coated piston.

|

|

- type:

- M14

1 Review Hide Reviews Show Reviews

-

Flawless

Works as intended